VSIP 2 Industrial Park (Binh Duong), September 8, 2025 – The technical team of Tai Phuoc Trading – Service – Engineering Co., Ltd., led by chief engineer Phan Van Doan, has completed a periodic inspection and maintenance package for FPT diesel engines serving the fire fighting system at the TAKIGAWA – VSIP 2 project (customer Taikisha).

Quick facts

| Customers |

Taikisha |

| Construction | TAKIGAWA – VSIP 2 |

| Device | Diesel FPT N45MNTF41.10 – 145 kW – Series No: 1027857 |

| Content | Check and change Diesel engine oil for fire protection |

| Execution unit | Tai Phuoc Trading – Services – Technical Company Limited |

| Engineer in charge | Phan Van Doan |

| Execution date | 08/09/2025 |

Background and tasks

The diesel engine in the fire pump system plays a crucial role in ensuring fire safety for the entire factory. According to the maintenance plan, the Tai Phuoc engineering team conducts a comprehensive inspection process, changes the oil – cleans, and evaluates the actual operating status after maintenance to ensure the equipment is always ready.

Progress at the scene

Work steps are implemented strictly, according to technical standards:

-

Confirm equipment information: Check model, serial, installation configuration and scope of work.

-

Overall inspection: Check appearance, pipes, pulleys, belts; Early detection of leaks or wear.

-

Check oil filter & oil level: Assess cleanliness and oil level within allowable limits.

-

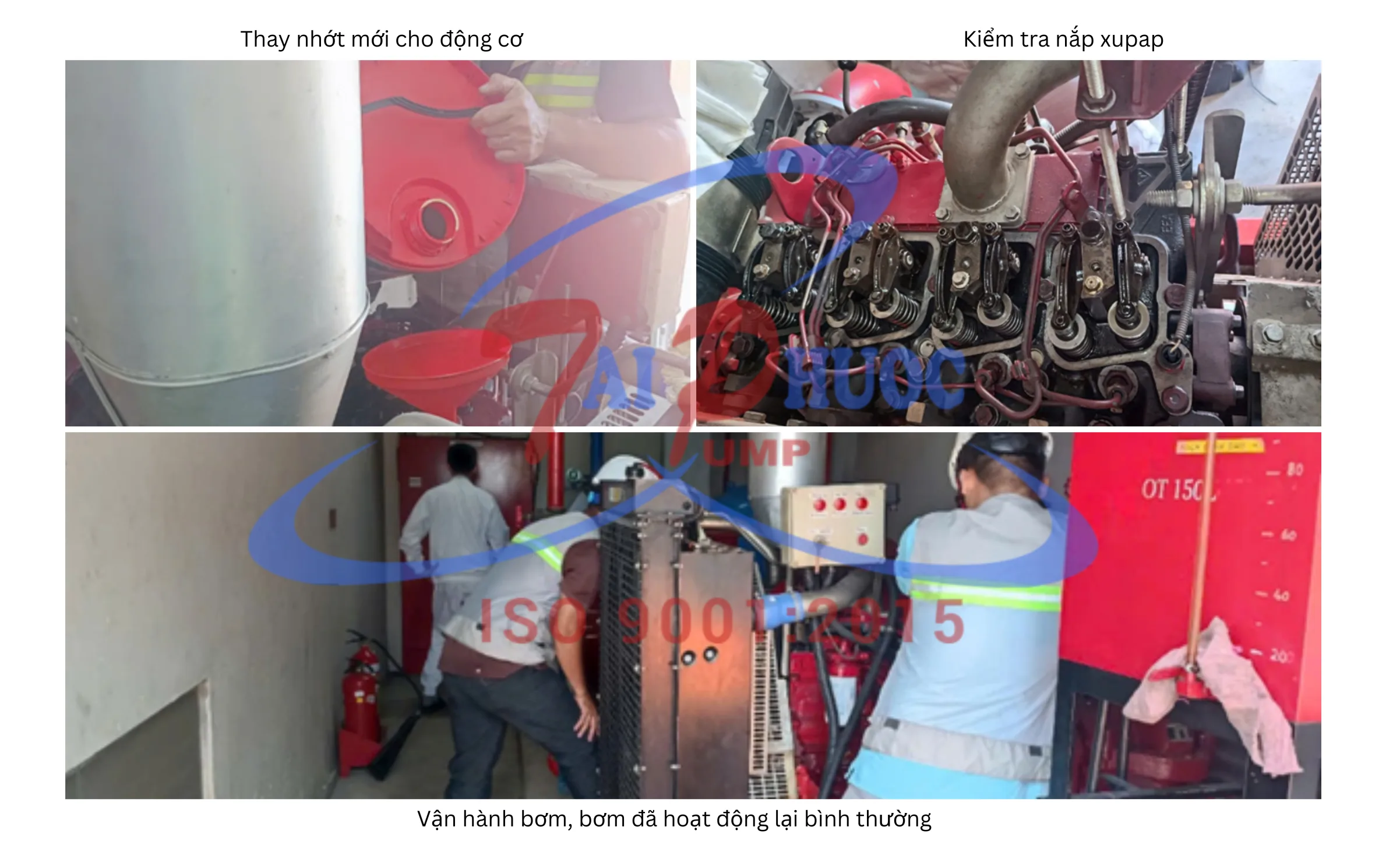

Change oil: Drain old oil, collect and process according to regulations; refill new oil of the correct type and capacity; Clean the entire working area.

-

Check the valve cover: Check for points at risk of leakage, tighten torque if necessary.

-

Test the engine: Start, monitor smoothness, vibration, noise; check pump load response and basic parameters.

Result: The engine started well, the pump operated stably, no oil leaks were detected. No abnormal signs of sound or vibration appeared during the test run.

Meaning of maintenance work

The Regular maintenance of the fire protection system not only helps the equipment operate safely but is also a mandatory requirement in fire prevention and fighting inspection. For large-scale factories like TAKIGAWA, each successful maintenance is a step to strengthen the belief that the system will operate smoothly when needed, minimizing the risk of production interruption and protecting assets and people. Ensuring regular maintenance is the way you improve the reliability of the entire system.

Recommended operation and maintenance

To maintain the durability and availability of the engine, Tai Phuoc recommends:

-

Change oil and filter regularly according to the manufacturer’s instructions to reduce the risk of wear.

-

Set up a periodic test log, record temperature, oil pressure, start-up time, noise and vibration.

-

Seal and mark the disassembly and assembly locations; update maintenance records for fire prevention and fighting inspection.

-

Synchronously check related items such as pump suction and discharge lines, valves and pressure gauges.

The on-site conclusion was confirmed by the engineer in charge: “Completed overall engine inspection and new oil change. No abnormalities detected. The engine is operating normally.” – Mr. Doan.

Contact Tai Phuoc today for advice and implementation of a periodic maintenance plan, helping your fire protection system always operate stably and safely.