HCMC, October 3, 2025 — The engineering team Tai Phuoc Pumps has successfully handled the cold vapor condensation problem in the chiller pump area of the Daiskin project, ensuring the equipment operates stably, safely and is absolutely dry.

Current status initial

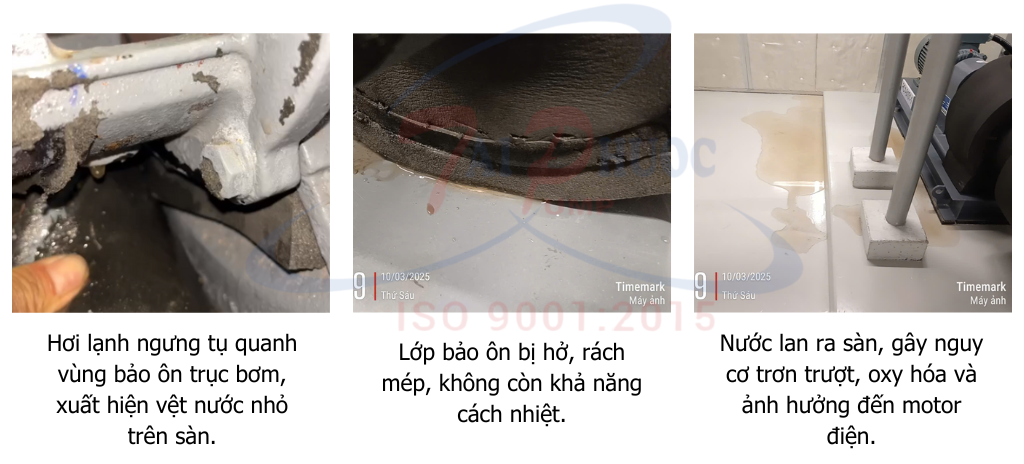

During the routine inspection on the morning of March 10, 2025, the Tai Phuoc engineering team recorded the phenomenon of water condensation and cold damp spots around the base of the chiller pump code P-CH-051.

Detailed inspection shows:

Cause analysis

After disassembly and on-site pressure measurement, the engineering team determined the main cause:

-

The mechanical seal is aging, leaking a little lubricating oil.

-

Open insulation around the pump shaft – cold air escaping meets humid air, creating condensation.

-

Lack of condensate drainage, causing water to accumulate and spread to the machine base.

Processing measures

Tai Phuoc engineering team will handle the problem on the same day:

- Clean and dry the entire machine base.

- Add new insulation around the pump shaft, sealing the joints and gaps.

- Add a condensate drain to prevent re-accumulation.

- Check the mechanical seal gas, lubricate and adjust the pump base bolts.

Result after processing

Pressure gauge 1.0 MPa after processing – recordedsystem stability after maintenance

-

Measured operating pressure: 1.0 MPa, stable within the standard range.

-

No more leaks or water accumulation around the seal pump.

-

The machine base area is dry, clean, and meets safety operation standards.

-

Technical report and acceptance photos Handed over to Daiskin Management Board

Recommended periodic maintenance

The Engineering Team – Tai Phuoc Pump Company recommends:

-

Replace the mechanical seal every 12 months.

-

Check insulation, drain condensate and lubricate the pump shaft every quarter.

-

Monitor pump pressure – vibration – temperature weekly.

Sharing from the field engineering team

“Each handling case is a real test of skills and responsibility.

We always put the safety and quality of our customers first — that is the culture of Tai Phuoc.”

— Phan Van Doan, Tai Phuoc Pumps Technical Team Leader

Don’t let a small incident become a big problem!

Tai Phuoc Pumps always accompanies you in every situation – from consulting, checking to on-site handling.

Contact us immediately for timely technical support. website: bomcongnghieptaiphuoc.com

Gmail:taiphuocco@gmail.com – Phone: 0913 415 166 (Service Support Staff) – 0903060563 (Technical Support: Phan Van Doan)